Did you know that many TPO roofing issues arise not from the roofing material itself but from HVAC installations? Understanding the intricacies of TPO roofing can help businesses reduce costs and improve repairs. In this post, we will dive deep into the predicaments of TPO roof repairs, highlighting how tears can occur due to HVAC company activities and why leaks may not originate where you think.

Understanding TPO Roofing and Its Vulnerabilities

TPO (Thermoplastic Olefin) roofing is favored for commercial properties due to its energy efficiency and affordability. However, like any roofing system, it comes with certain vulnerabilities that can have serious implications for business owners. One common issue arises from improper installations, including malfunctioning HVAC systems. If an HVAC unit is not mounted or sealed correctly, it can inadvertently damage the TPO roofing, leading to unnecessary repairs that could have been avoided.

Potential Causes of TPO Roofing Tears

TPO roofs are susceptible to damage from various sources, including:

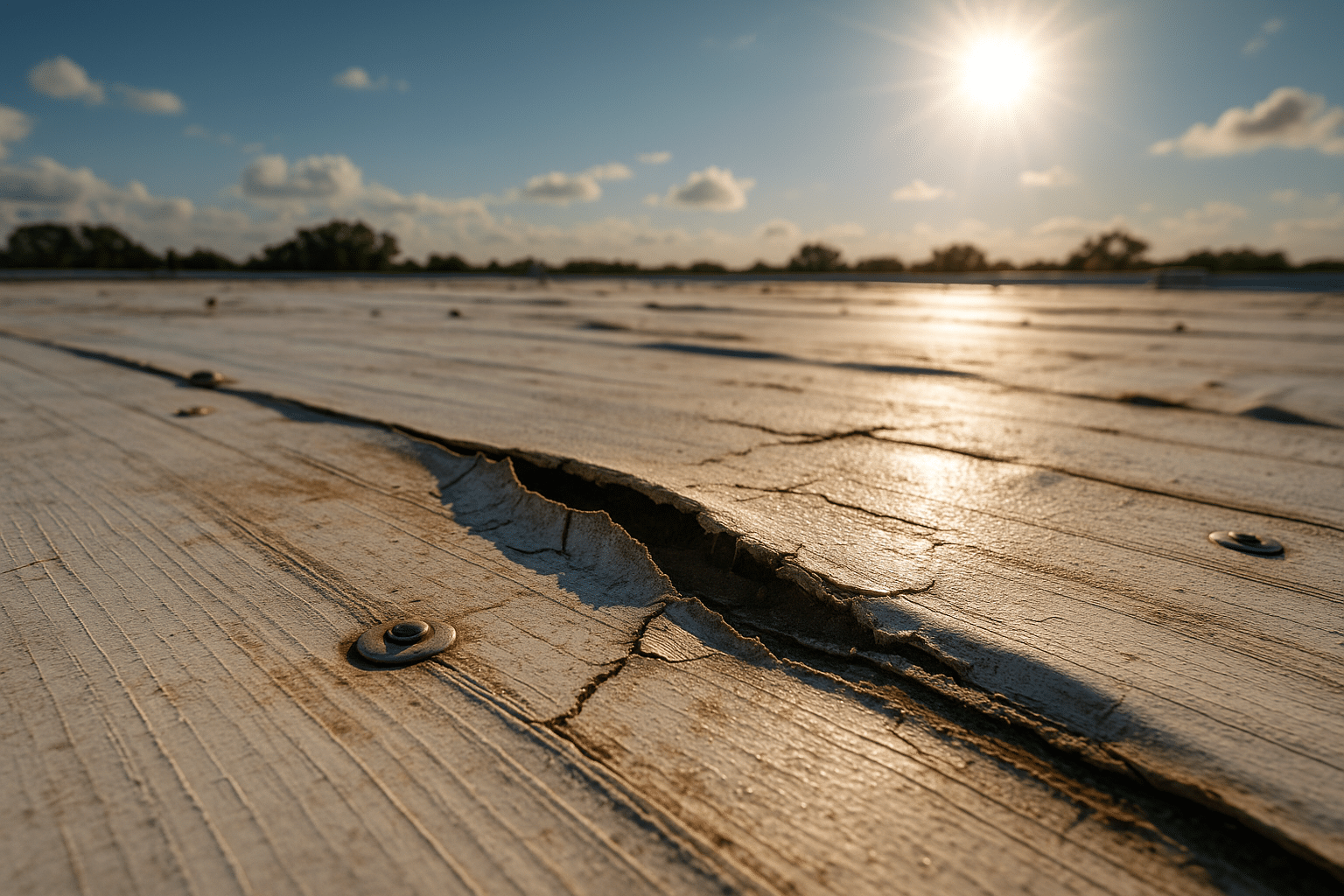

- HVAC Installation: When HVAC systems are not adequately installed, equipment can come into contact with the roof membrane, leading to tears. The weight of the HVAC unit coupled with improper support can exacerbate this issue, causing stress on the roofing material.

- Thermal Expansion: Changes in temperature lead to expansion and contraction within the TPO material, and if expansion is uneven, it can create tears over time.

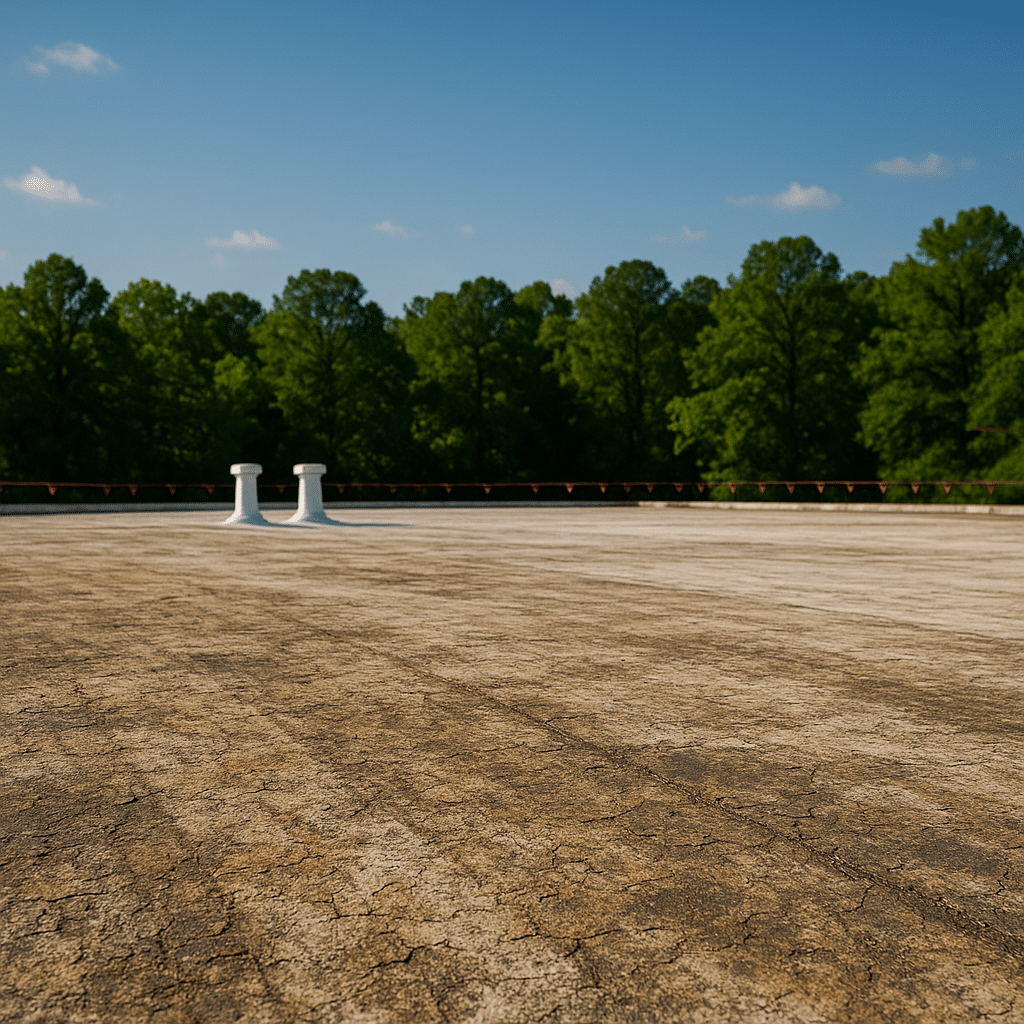

- Improper Maintenance: Regular maintenance is crucial for extending the lifespan of TPO roofs.

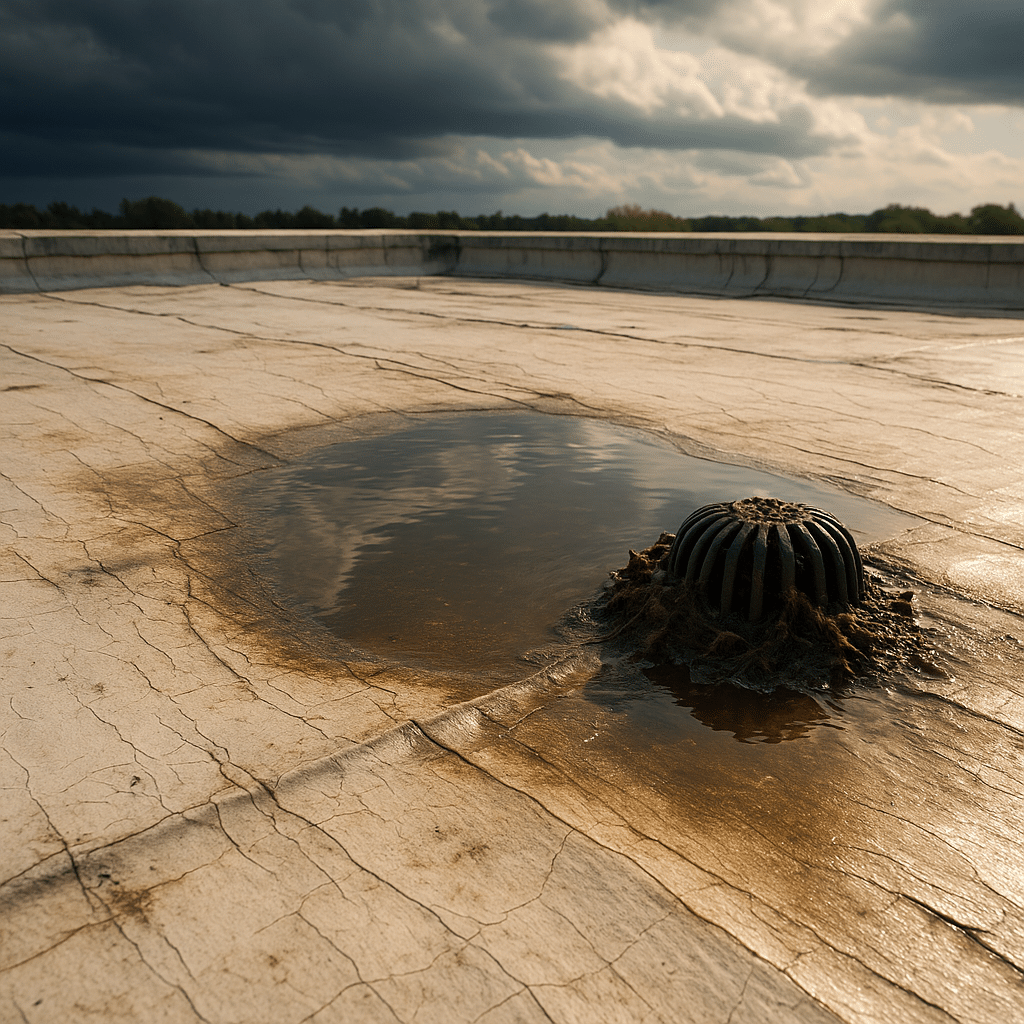

The Misconception About Leak Locations

A common misconception about TPO roofing is that leaks will be directly above where the tear or damage is located. However, water movement on roofs often travels along various channels and can infiltrate areas far from the actual tear. Therefore, while a leak might be visibly seen in one area, the root cause may be situated several feet away. This can lead to inefficient repairs where the visible leak is addressed, but the underlying issue goes unresolved, creating further complications.

Identifying the True Source of TPO Roof Leaks

To effectively address and repair leaks on TPO roofs, it’s essential to have a thorough inspection process that aims to identify water movement and not just visible signs of damage.

Here are some techniques that can assist in uncovering the source of leaks:

- Water Testing: Skilled technicians can perform water tests that simulate rainfall, allowing them to observe water behavior and track down leaks.

- Infrared Scanning: This technology enables inspectors to see temperature differentials on the roof, which can indicate areas where moisture is present, regardless of visible signs.

- Visual Inspection: It’s crucial for roofing professionals to inspect seams, flashings, and HVAC connections to identify potential weak points.

Preventative Strategies for Protecting TPO Roofs

Taking a proactive approach can save time, money, and resources in the long run. Here are some preventative strategies:

- Choose the Right HVAC Installer: Working with qualified HVAC professionals who understand how to interact with TPO roofing systems minimizes the risk of damage.

- Regular Inspections: Implement a routine inspection schedule to catch potential issues before they escalate into costly repairs.

- Educate Staff: Often, employees may inadvertently contribute to roof damage, so educating them about the necessity of keeping the roof clear of debris and other materials can help maintain its health.

- Proper Maintenance: Timely repairs of minor tears or holes can prevent larger issues over time, so incorporating a proactive maintenance agenda is crucial.

Repairing TPO Roofs: Steps to Take

When it comes to repairing a TPO roof, timely intervention is critical to prolonging its lifespan. Here are steps to follow:

- Consult a Roofing Professional: Not all roofing situations are equal, so seeking help from an experienced roofing professional familiar with TPO systems is essential for accurate assessment.

- Thorough Assessment: This early assessment should include visual checks and testing methods to provide a comprehensive picture of the roof’s condition.

- Repair and Sealing: If tears or holes are found, they should be patched promptly using materials designed to bond with TPO. Ensuring seams and joints are sealed correctly is equally important in the repair process.

- Follow-Up Inspections: After repairs, continued inspections are essential to ensure no further issues arise.

Final Thoughts

Understanding the dynamics of TPO roofing repairs, particularly how tears can occur due to HVAC influences and how leaks often travel away from the site of damage, is fundamental for maintaining your investment. Having an informed approach enables business owners to mitigate risks associated with TPO roofing installations, benefiting from their operational efficiency and longevity. Regular inspections, quality installations, and swift repairs can ensure your TPO roof remains intact, safeguarding your investment and maintaining operational flow.

Consider implementing a routine maintenance plan today! A proactive approach can save you significant costs in repair needs over time.